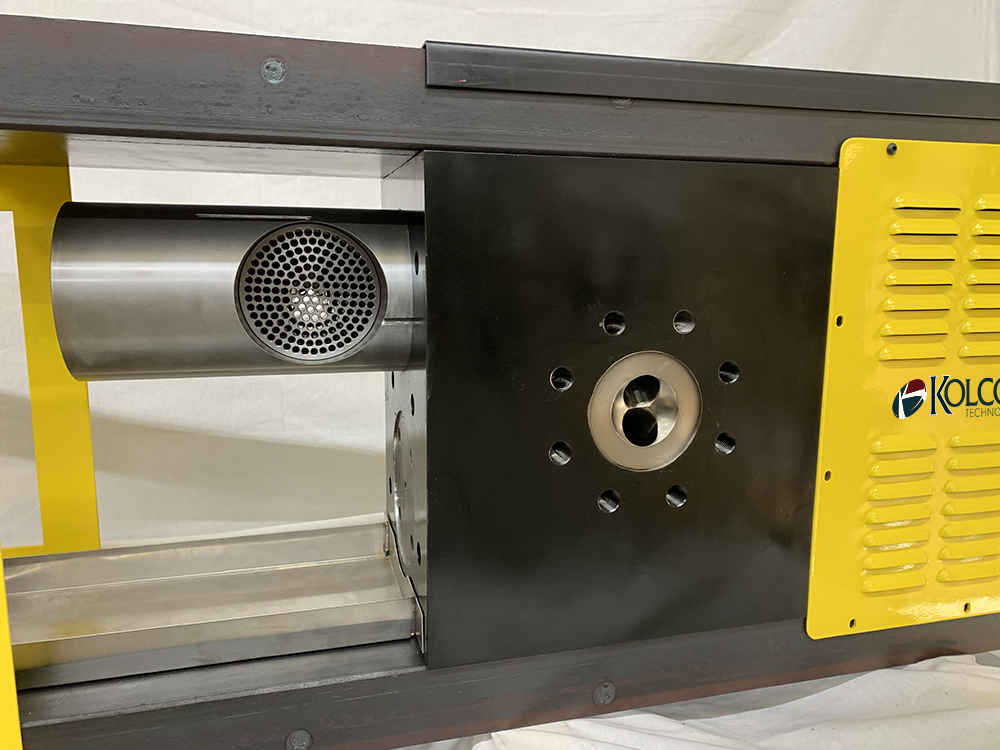

DB Series Screen Changers Save Time and Money

Unlike other screen changers that introduce an air bubble into the melt stream, or even require the extruder to be shut down, the DB filters out contaminants and provides a means for replacing dirty filters while maintaining a continuous melt flow

Features

- Continuous filtration

- Dual breaker plates

- Precision machining

- Automated controls

- One-sided changing

- Drip pan

- FEA design

- Integrated guards

Benefits

- No interruption in melt flow means less scrapped material and reduces the chance of cavitation

- Filtration continues while screens are being replaced

Eliminates the need for seals - Day to day operation requires little training

- Keeps hydraulic and electrical components clean

- Simplifies polymer removal

- Ensures customers safety while keeping costs lower

- Protects customer from pinch, crush and burn

- injuries

Applications

- Sheet

- Blown film

- Wire and cable

- Profile extruding

- Pipe

- Tubing

- Pelletizing

- Reclaim/Recycling

413-821-8948

413-821-8948

sales@kolcor.com

sales@kolcor.com